Is it a viable option for feeding sheep, goats and other livestock?

|

| Year-round production |

Although the methods of hydroponic fodder production date back to the 1930's, there is renewed interest in hydroponic fodder as a feedstuff for sheep, goats, and other livestock.

Hydroponics is a method of growing plants without soil. Only moisture and nutrients are provided to the growing plants. There are many advantages to hydroponics. Hydroponic growing systems produce a greater yield over a shorter period of time in a smaller area than traditionally-grown crops.

There is a reduction or exclusion of pesticides and herbicides because the plants are in a more protected growing environment. Hydroponics is a year-round growing system that produces a consistent quantity and quality of plant material, regardless of outside weather.

Fodder (livestock feed) can be grown hydroponically much the same as vegetables, flowers, and other plants. Hydroponic fodder systems are usually used to sprout cereal grains, such as barley, oats, wheat, sorghum, and corn, or legumes, such as alfalfa, clover, or cow peas. Barley is the most commonly grown forage, because it usually gives the best yield of nutrients (4). Forage mixtures are another option.

A hydroponic fodder system usually consists of a framework of shelves on which metal or plastic trays are stacked. After soaking overnight, a layer of seeds is spread over the base of the trays. During the growing period, the seeds are kept moist, but not saturated. They are supplied with moisture and (sometimes) nutrients, usually via drip or spray irrigation. Holes in the trays facilitate drainage and the waste water is collected in a tank.

The seeds will usually sprout within 24 hours and in 5 to 8 days have produced a 6 to 8 inch high grass mat. After the mat is removed from the tray, it can go into a feed mixer or be hand-fed to livestock. Livestock will eat the whole thing: seeds, roots, and grass. There is minimal waste. Livestock may not eat the fodder initially because it is novel, but should soon learn to eat it with relish.

|  |  |

| Hydroponic fodder systems make very efficient use of water and land. |

While it is possible to grow hydroponic fodder in any building, including a garage or basement, a greenhouse is ideal because temperature, light, and humidity can be precisely controlled. Efficient, year-round production of green fodder is not possible unless environmental conditions are optimal: approximately 70°F, 60 percent humidity, and 16 hours of light. For this reason, hydroponic growing systems usually require significant investment.

Hydroponic fodder systems come in a range of sizes and capacities. Large fodder sheds may produce several tons of fodder per day, whereas a mini-fodder system may produce only 10 lbs. per day. It is possible to build your own system, or a "turn-key" system can be purchased from a commercial company. Investments range from a few hundred dollars to six figures.

As feed for livestock

Fodder sprouts are tender and young, the equivalent of fresh green grass. As such, they are highly palatable and nutritious to all types and classes of livestock. On a dry matter basis, hydroponic fodder compares favorably with other nutritious feedstuffs.

| Comparative nutrition of different feedstuffs (DM) | |

| Feedstuff | % CP1 | % TDN1 | mcal/kg | |

| ME1 | NEm1 | NEg1 | NEl1 | |

| Alfalfa Hay | 17 | 58 | 2.1 | 1.3 | 0.6 | 1.3 | |

| Barley grain | 12 | 84 | 3.0 | 2.0 | 1.3 | 0.9 | |

| Barley sprouts3 | 21 | 71 | 2.6 | 0.75 | 0.47 | 0.74 | |

| Orchardgrass, fresh | 24 | 65 | 2.4 | 1.5 | 0.8 | 1.5 | |

| Orchardgrass hay | 10 | 59 | 2.1 | 1.3 | 0.6 | 1.3 | |

| Soybean meal | 49 | 84 | 3.0 | 2.0 | 1.3 | 1.9 | |

Sprouting changes the nutritive characteristics of the grain. Enzymes break down storage components into more simple and digestible fractions; for example, starch to sugars, proteins to amino acids, and lipids to free fatty acids. There is an increase in fiber and some vitamins and a decrease in phytic acid, an anti-nutritional factor (11).

With sprouting, there is a reduction in total energy. The increase in protein percentage is due to the dry matter loss . In fact, the downside to hydroponic fodder is its high moisture content. According to various forage analysis reports (3), the dry matter content of hydroponic fodder is only 12 to 15 percent, compared to almost 90 percent in (unsprouted) grains and hays (1). Even corn silage and haylage have considerably more dry matter than sprouts (1).

If you do not consider its high moisture content, the per pound price of hydroponic fodder seems very economical, around $0.06 per pound (or $120 per ton) (3). Without further analysis, this sounds like a great way to reduce the cost of feeding livestock. But when the wet cost is converted to a dry matter basis, feed cost becomes very high. At 12 percent dry matter (DM), wet feed that costs 6 cents per pound actually costs 50 cents per pound of dry matter. This is considerable more expensive than most other feedstuffs, as shown in the tables below.

| Comparative costs of different feed costs (as-fed) |

| Feedstuff | Cost | Unit | $/lb |

| Barley sprouts3 | $0.06 | pound | 0.060 |

| Orchardgrass hay | $60 | 700-lb bale | 0.086 |

| Alfalfa Hay, mid bloom | $250 | ton | 0.125 |

| Barley grain | $6 | bushel | 0.125 |

| Soybean meal | $480 | ton | 0.240 |

| Cost per pound of dry matter (DM) |

| Feedstuff | $/lb | % DM1 | $/lb DM |

| Alfalfa Hay | 0.125 | 89 | 0.14 |

| Barley grain | 0.125 | 89 | 0.14 |

| Orchardgrass hay | 0.086 | 88 | 0.20 |

| Soybean meal | 0.24 | 91 | 0.26 |

| Barley sprouts3 | 0.063 | 123 | 0.50 |

Because of its low dry matter content, the cost of nutrients in hydroponic fodder is also considerably more expensive than other feedstuffs.

| Cost per pound of energy (TDN) |

| Feedstuff | $/lb DM | % TDN1 | $/lb TDN |

| Barley grain | 0.14 | 84 | 0.17 |

| Orchardgrass hay | 0.10 | 58 | 0.17 |

| Alfalfa Hay | 0.14 | 58 | 0.24 |

| Barley sprouts3 | 0.50 | 71 | 0.70 |

| Cost per pound of protein (CP) |

| Feedstuff | $/lb DM | % CP1 | $/lb CP |

| Soybean meal | 0.26 | 49 | 0.54 |

| Alfalfa hay | 0.14 | 17 | 0.82 |

| Barley sprouts3 | 0.50 | 21 | 2.40 |

Nutritional requirements of livestock are based on dry matter intake. If fed to livestock at a rate of 2 percent of their body weight (a common recommendation), hydroponic fodder will only meet a fraction of most animals' nutritional requirements, especially the higher producing ones. Thus, hydroponic fodder, while excellent feed, is only a nutritional supplement and an expensive one at that.

| Energy (TDN) requirements met by feeding fodder @ 2% BW (as-fed) | |

Animal

Stage of production | lb. fodder fed | lb. TDN

supplied

by fodder | TDN requirements

lb. DM/day1 | % TDN requirements met by hydro fodder | |

| As-fed | DM | |

154-lb. ewe

maintenance | 3.08 | 0.37 | 0.26 | 1.36 | 19.3 | |

154- lb. ewe

late gestation, twin lambs | 3.08 | 0.37 | 0.26 | 2.66 | 9.9 | |

154-lb. ewe

early lactation, twin lambs | 3.08 | 0.37 | 0.26 | 2.88 | 9.1 | |

176-lb. ewe, parlor milked

(5.2-8.7 lbs milk/day) | 3.52 | 0.42 | 0.30 | 4.42 | 6.8 | |

Growing, 44-lb. Boer buck

( 0.44 lb/day) | 0.88 | 0.11 | 0.07 | 1.41 | 5.3 | |

Growing, 66-lb. lamb

(4 mos. old, 0.66 lb/day) | 1.32 | 0.16 | 0.11 | 2.18 | 5.2 | |

132-lb. doe, parlor milked

(10-14 lbs milk/day) | 2.64 | 0.32 | 0.22 | 5.50 | 4.1 | |

Calculations in table

lb. fodder fed (as-fed) = BW x 0.02. [Example: 154 lbs. x 0.02 = 3.08 lbs. as-fed]

lb. fodder fed (DM) = lb. fodder fed (as-fed) x 0.12 (% DM). [Example: 3.08 x 0.12 = 0.37 lbs DM fed]

lb. TDN supplied by fodder = lb. fodder fed (DM) x 0.71 (% TDN). [Example: 0.37 x 0.71 = 0.26 lbs. TDN]

% TDN supplied by fodder = lb. TDN supplied by fodder ÷ TDN requirements (DM). [Example: 0.26 ÷ 1.36 = 19.3% of TDN requirements] | |

Full feeding of sprouts is usually inappropriate due to the high moisture content of the feed, the high cost of the feed, and the scale which would be needed to produce sufficient dry matter (11).

Animal performance

|

| Pigs eating fodder |

The companies that market hydroponic fodder systems make many claims about hydroponic fodder as superior livestock feed: better gain, improved fertility, earlier heat cycles, improved fleece quality, improved immunity, better behavior and temperament, less manure, etc. Few of these claims have been substantiated or proven to be repeatable in experiments (5,11).

Over the years, in many different countries, and with different species (mostly cattle, pigs, and poultry), research trials have been conducted to assess the performance of livestock fed hydroponic green fodder (11). Across the many trials, there has been no consistent advantage to including green fodder in the diet of livestock, especially when it replaces highly nutritious feeds, such as grain (5,7). Even if there are benefits to hydroponic fodder, the benefits are usually outweighed by the costs.

Research is conflicting as to whether sprouting improves or reduces dry matter digestibility as compared to the raw grain. In a 2012 journal article, Iranian researchers reported no increases in quantity or quality of dry matter and nutrients with sprouting (10). While the companies claim that you'll get a 6 to 10-fold increase in weight from a pound unsprouted grain, they fail to mention that the increase (in weight) is almost all water (5,11).

At the same time, there is a strong need for more trials to determine the potential feeding value of hydroponic fodder, particularly with sheep and goats. Studies conducted in Italy in 2009 produced conflicting results with regards to milk production and welfare of sheep and goats (2,8). Another aspect that needs to be investigated is potential changes in the final product (meat and milk) as a result of replacing some of the animals' traditional diet with green fodder.

Other challenges

One of the biggest challenges to producing hydroponic fiber, especially commercial quantities, is mold (5, 11). Moldy sprouts can decrease animal performance and result in animal deaths (5, 11). Pre-treatment of seed with a sterilizing agent (e.g. hydrogen peroxide) is one strategy for preventing mold. Good hygiene in the system is also important. It is recommended that the growing trays be cleaned between crops with a chlorine based cleaning solution (11).

| |  |  |

| The downside to hydroponic fodder is its high moisture content. |

Hydroponic fodder production requires a lot of labor. Time is needed to soak the seed, make up the nutrient solution, transfer the grain to the trays, load the trays onto the shelves, check the fodder daily for growth, remove the sprouted grain from the trays, wash and sterilize the trays, and feed the fodder to the livestock. Automation will reduce labor requirements, but may substantially increase investment costs.

In order to create a controlled growing environment, it can require considerable energy to grow hydroponic fodder (5). Solar power could be used to provide electricity, especially in remote, rural areas or third world countries.

Advantages of hydroponic fodder

Hydroponic fodder has several advantages over conventionally-produced fodder. Hydroponic fodder makes very efficient use of water (4,5,11). There is little waste water, as animals consume the recirculated water along with the feed. Since production is hydroponic, there is no leaching of nutrients into the environment. Hydroponic fodder production requires considerably less land to produce feed for livestock.

While hydroponic fodder is not likely to become a major source of feed for commercial livestock, it could be feasible under certain circumstances.

Dry and drought-prone regions

Hydroponic fodder production is probably best-suited to semi-arid, arid, and drought-prone regions of the world. By growing fodder indoors, crop failures would no longer be a risk. Good quality forage could be produced year-round. Feed supplies would be insured. Scarce water resources could be allocated more efficiently (4).

Limited land

In places where land values are extremely high or land is simply not readily available, hydroponic fodder has obvious advantages, as it can be produced in a small footprint. Because the fodder is produced continuously, there is no need for long-term feed storage and no nutrient losses that can be associated with feed storage.

High alternative feed costs

While this article clearly shows that hydroponic fodder is considerably more expensive than conventional feedstuffs, it assumes that conventional feedstuffs are available and priced competitively. There are many locations in which this is not the case and hydroponic fodder could be more competively priced.

Small-scale producers

Requiring smaller amounts of fodder, small-scale producers may be able to build their own fodder systems for a few hundred dollars. When the investment is low and labor is unpaid, the cost of hydroponic fodder is considerably less.

|  |  |

| You can build a mini-fodder system for a minimal cost. |

Non-ruminants

Hydroponic fodder may be best-suited to non-ruminants (horses, rabbits, pigs, and poultry) who would benefit more from the changes in the feed due to sprouting (e.g. less starch, more sugars) as compared to ruminants (sheep, goats, and cows) who are less efficient at digesting high quality feed (6). Hydroponic fodder seems ideal for horses, though the research is lacking. A study with rabbits showed no detrimental effect to replacing up to 50 percent of the commercial diet with green fodder (9).

Organic

Hydroponic fodder production seems particularly well-suited to organic producers (6), who already pay high prices for feed or have difficulty sourcing organic feedstuffs. Cereal grains can easily be sprouted in accordance with USDA's Certified Organic Program.

In the future

As competition for land and water increases and feed prices continue to rise, hydroponic fodder could become a viable option for more livestock producers.

References 1Nutrient Requirements of Small Ruminants (2007) - National Research Council 2Evaluation of animal welfare and milk production of goat fed on

diet containing germinating seeds (2009) - Italian Journal of Animal Science 3Fodder Pro (FarmTek) (2012) 4Green fodder production and water use efficiency of some forage crops under

hydroponic conditions (2011) - ISRN Agronomy 5Hydroponic fodder production: an analysis of the practical

and commercial opportunity (2011) - The New Zealand Merino Company 6Hydroponic fodder systems for dairy cattle (2013) - Iowa State University 7Performance of feedlot calves fed hydroponics fodder barley (2011) - J. Ag. Sci & Tech 8Improvement of sheep welfare and milk production fed on diet containing

hydroponically germinating seeds - (2009) Italian Journal of Animal Science 9Productive response of rabbits fed with green hydroponic oats forage as

partial replacement of commercial concentrate (2011) - Acta Agronomica 10Productivity and nutritive value of barley green fodder yield in hydroponic

systems (2012) - World Applied Sciences Journal 11Review of hydroponic fodder for beef cattle (2003) - Meat & Livestock Australia

Source:

http://www.sheepandgoat.com

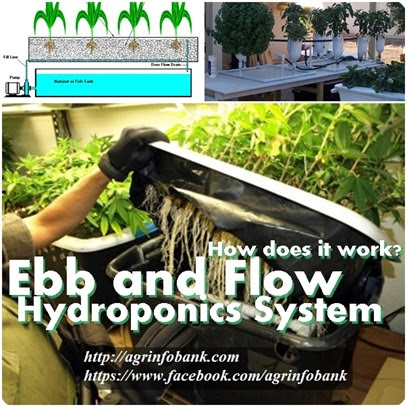

Ebb and flow hydroponics is a method of growing plants hydroponically that is known for its reliability, simplicity of operation and low cost of investment. Pots or a flood tray are filled with a grow media such as gravel, clay pellets, lava rock etc. These do not function like soil or add nutrition to the plants but will anchor the roots and will function as a temporary reserve of water and nutrients. The hydroponic solution floods the system four to six times a day and is allowed to drain away in between flood cycles.

Ebb and flow hydroponics is a method of growing plants hydroponically that is known for its reliability, simplicity of operation and low cost of investment. Pots or a flood tray are filled with a grow media such as gravel, clay pellets, lava rock etc. These do not function like soil or add nutrition to the plants but will anchor the roots and will function as a temporary reserve of water and nutrients. The hydroponic solution floods the system four to six times a day and is allowed to drain away in between flood cycles.